Originally posted on the Hobart Forum by TRG-42

Pictures added and facts checked by Andrew Booker

When people tell you about how difficult propane is to cut when compared to acetylene they are not really providing you with all the information.

FACT :The difference doesn't really matter as the real concern is for the thermal output ( BTUs ).

FACT :So when they say propane gives off less heat it is not entirely correct ( plain wrong actually ). In the welding industry the vast majority of preheating is done with Oxygen / Propane . This is a fact . They don't do it just because it's cheaper but because the available heat from propane is much higher.

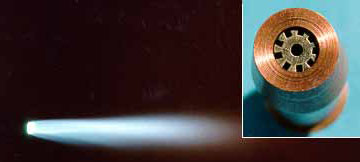

FACT : If you look at any torch manufacturers catalog, you will see Propane, Propylene and MAPP heating tips / nozzles of 250,000 btu/hrs to 1,000,000 btu/hrs. But if you look at the Acetylene heating tips / nozzles the maximum you see in the Harris catalog is a relatively small 240,000 btu/hrs, Smith Acetylene heating tip / nozzles are slightly less than 200,000 btu/hrs and Victor is about 300,000 btu/hrs. These are all far less than what they make for Oxygen / Propane use.

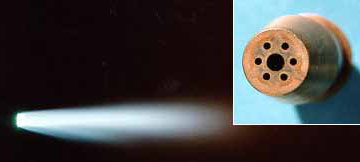

For years people professed that Acetylene was better for cutting then Propane . While temperature wise Acetylene is hotter than Propane the fact is that they were using Propane for cutting incorrectly. The mistake they make is that they are cutting with Propane like they would cut with Acetylene. It turns out "where" the heat is in the propane preheat flame is not where it is with Acetylene.

FACT : Propane releases only a small proportion of heat in the inner flame cone ( less than 10% ), so most of the heat in the flame is in located in the outer cone . Acetylene releases almost 40% of its heat in the inner flame cone.

If you cut with acetylene you normally put the tip of the inner flame cone on the metal. If you do the same with propane you will be waiting for a long time. If you raise the torch so that the outer flame cone is used the preheat process is started faster . Is it necessarily as fast a preheat as Acetylene, no but it is nowhere as poor as most people think.

FACT : Just about all industrial plate cutting operations today not using Plasma Cutting Technology ( CNC tables ) are normally done with Oxygen / Propane or Propane derivatives. If you watch these tables cut, it will simply amaze you how quickly they can start a cut on 1" and over plate using the lowly Propane gas.

Propane has a greater stoichiometric oxygen requirements than acetylene: for the maximum flame temperature in oxygen, the ratio of the volume of oxygen to fuel gas are 1:2 to 1 for acetylene and 4.3 to 1 for propane. there is far more oxygen being used in the cutting orifice than there is being fed into the preheat mixer tube of the tip. So the numbers look in favour of Acetylene but it's not as bad as you were initially lead to believe.

Lots of conjecture out there on why you can't weld with propane. Some say Propane is not hot enough. Actually that has nothing to do with it. Take a #7 Oxygen / Propane tip and compare it to a tiny #1 welding tip. Even though the Propane tip has a far higher BTU output you still will not get a good weld. The reason Propane ( and other alternative fuels ) are not suitable is that when Acetylene is burning with Oxygen it creates a cone of CO2 forming a shielding gas over the weld puddle. Propane does not produce this shielding CO2.

The bottom line is there are may people who will not be conviced Propane is a good cutting fuel gas, which is fine, but the performance difference is not as bad as some of Acetylene advocates would lead you to believe.

To download and print a Victor Propane Cutting Tip / Regulator Setting Chart click *** here ***